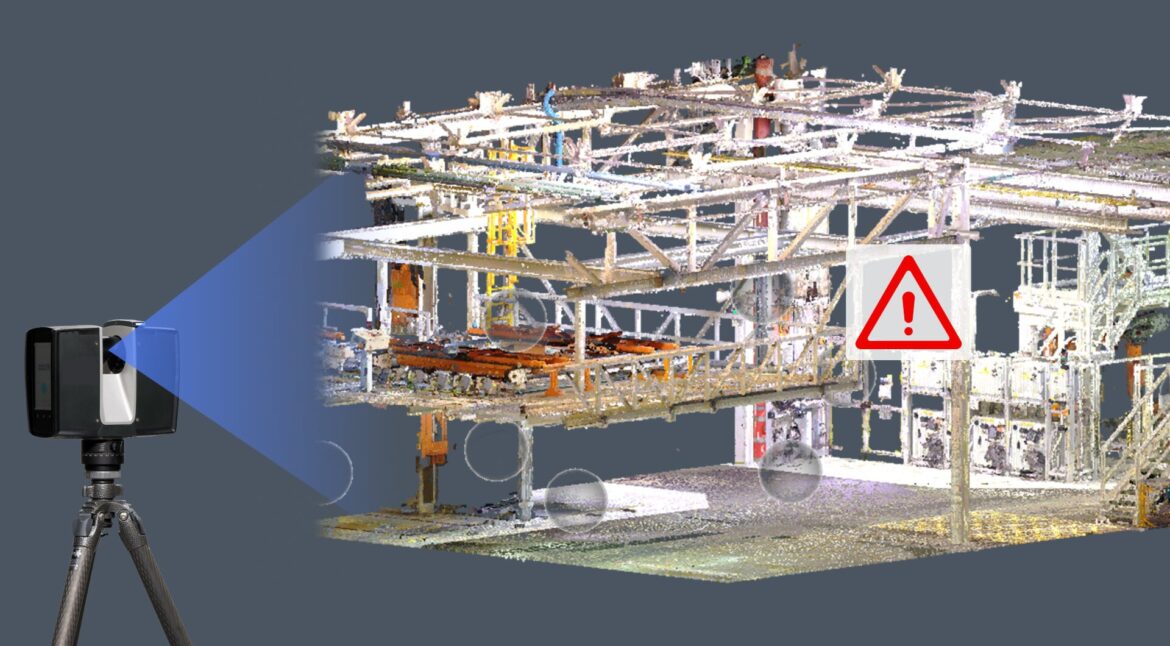

With an ever-changing technological world, 3D scanning has developed as an important tool for capturing things and real-world surroundings with unprecedented accuracy. It is particularly important in domains such as industrial analysis, archeology, and digital entertainment; nonetheless, successful 3D modeling requires much more. However, scan quality is still an unattainable aim. Filling in noisy data for missing patches in undesirable artifacts numerous factors can degrade the realism of scanned models. In this post, we will look at frequent barriers to 3D scan quality and effective mitigation techniques.

Typical Challenges with 3D Scan Quality

Noise and Artifacts

Environmental conditions, scanning technology constraints, and environmental factors like uneven lighting, noise, and artifacts in 3D scans can impair accuracy and visual quality. To reduce their negative effects on scan quality, these abnormalities or discrepancies in scanned data must be carefully considered while choosing scanning strategies and post-processing processes.

Missing Data

Missing data from complicated or occlusion-prone areas of an object that are out of the scanner’s reach poses a serious problem to three-dimensional scanning. The finished model may include gaps or holes as a result, which would compromise its integrity and completeness. To avoid this, sophisticated scanning methods such as adaptive scanning strategies and multi-view registration can be employed to optimize the Point Cloud to Revit Modeling Process for complicated geometries, capturing numerous perspectives and guaranteeing a smooth and accurate representation of the object being scanned.

Data Alignment

For large or complex elements, in particular, alignment problems are essential to the creation of a cohesive 3D representation. Glitches, overlaps, and fragments brought on by misalignment might result in mistakes. It is crucial to use specialist software tools for accurate calibration and registration of scan data. A final model structure’s soundness and misalignment issues can be minimized by carefully planning and carrying out the scanning procedure.

Data Processing

Other problems that impact quality arise throughout the processing and analysis stage of 3D pictures, in addition to Laser Scanning for Historic Building. Due to data processing problems brought on by the enormous amount of data generated during 3D scanning, accuracy or efficiency losses may occur. The process is more difficult when complex objects are scanned, frequently producing noises and distortions.

Techniques for Improving the Quality of 3D Scans

Scan Cleanup

To obtain precise 3D scanning, scans must be cleaned up before being processed by photogrammetry or scanning software. Such objects as dust, reflections, shadows, or people need to be removed to avoid causing problems with the image alignment and reconstruction. To minimize artifacts and reduce noise, the object and scanning environment must be set up before the scanning process starts.

Optimize Your Settings

To achieve the best scan quality, the scanning parameters such as resolution, exposure, and point density must be carefully adjusted. You can try different settings to determine the best setup for capturing the preferred level of detail while minimizing noise and other artifacts. Besides, setting adjustments according to the object’s specific attribute and scanning environment can boost the quality of scanned data.

Refine Your Meshes

Enhancing scanned meshes and Eliminating imperfections is crucial. These methods help refine surfaces, close gaps, and trim parts of the model. Cutting edge techniques and tools streamline the refining process guaranteeing a representation of the shape of the object.

Generate Your Textures

The visual realism and aesthetic appeal of this 3D model are improved by adding textures to it. The texture mapping techniques allow the use of high-resolution images taken from the scans for a better blending together with geometry. This develops a texture that can represent the characteristics that exist on the surface of such an object in scanned items and improves their quality.

Test Your Results

To identify any issues during the process, it is necessary to regularly evaluate the quality of scanned models. These can be checked against reference models or by carrying out accuracy tests with familiar objects and features. Detecting missing data, alignment errors or other artifacts can be done by testing the results; this helps in making appropriate changes to the scanning workflow.

Adjust Your Workflow

To achieve an efficient 3D scanning workflow, an individual has to be adaptable and flexible. Regardless of the Scan to BIM Services Project, a workflow must be adjusted to suit these demands. This might entail altering scanning techniques, improving post-processing protocols, or adding extra quality assurance steps in a bid to have perfect outcomes.

Wrapping Up

In summary, the enhancement of 3D scan quality is a matter of technical know-how, keenness to detail, and a systematic approach to deal with common difficulties. Practitioners can however improve on this by applying the advice given in this article, which ranges from cleanup of images and optimization of settings; mesh refining and texture generation; testing obtained outcomes, and modifying workflows that will minimize missing information and artifacts resulting in better scan quality as well as its accuracy.