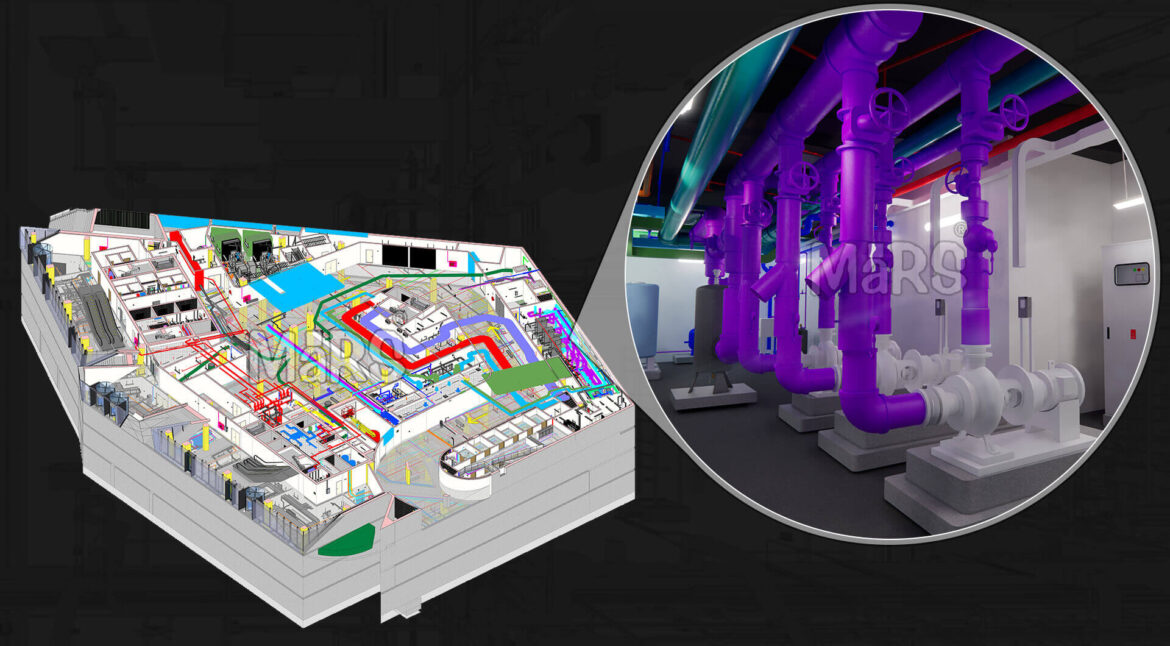

These days, MEP 3D modeling services are necessary for project success in the construction industry. The systems that are essential to any building are mechanical, electrical, plumbing, or MEP systems. Efficient design, coordination, and execution of these systems require advanced modeling techniques due to their complexity.

What is MEP 3D Modeling?

MEP modeling involves modeling a building’s mechanical, electrical, and plumbing systems in 3D. Contractors, engineers, and architects can now see how these systems will work together in the real world because of this modern method. In contrast to conventional 2D drawings, MEP BIM Modeling Services provide a comprehensive perspective that helps stakeholders spot possible conflicts and fix them before construction begins.

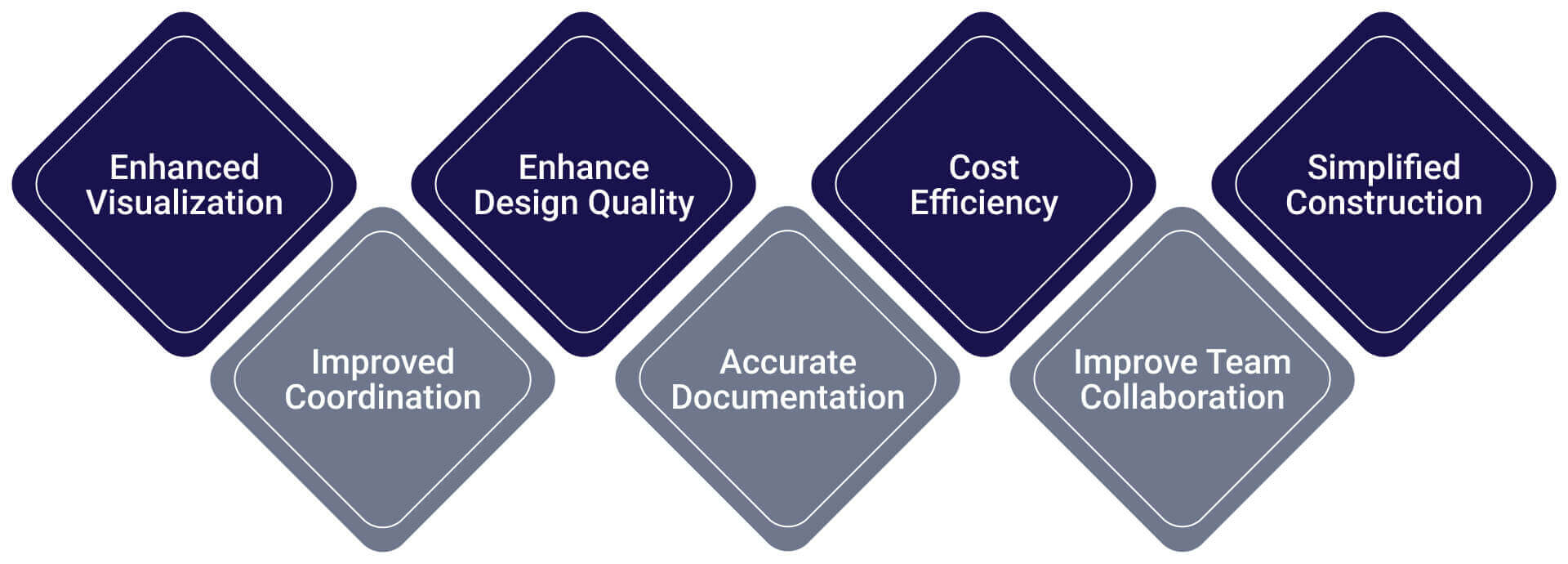

Benefits of MEP 3D Modeling in Construction Projects

Enhanced Visualization

The architecture of a building can be represented using mechanical 3D modeling. Project teams can communicate more effectively and understand the design intent better with the aid of this visual.

Improved Coordination

The capability of MEP BIM Services to coordinate multiple systems in a single model is a major benefit. By reducing conflicts between different fields, this integration lowers the rework expense during the building stage.

Enhance Design Quality

Modeling and optimization are made easier by advanced analysis and linear design tools, which guarantee excellent designs from concept to finished shop drawings.

Accurate Documentation

Specific documentation, such as installation instructions and specifications, is produced by MEP BIM models. This accuracy guarantees that all stakeholders agree with the project specifications, resulting in greater compliance with building standards and requirements.

Cost Efficiency

Mechanical 3D modeling reduces change orders and delays by seeing potential issues early in the design phase. Costs are significantly reduced by using this proactive approach throughout the project.

Improve team collaboration

Create a centralized digital source of truth available to all parties involved to improve teamwork. You can make sure that everyone in the project team has access to correct information at all times by connecting your model to the cloud. This will allow for smooth interaction and involvement.

Simplified Construction

With detailed Mechanical 3D Modeling Services, contractors can plan and execute installations more effectively. This not only speeds up the construction process but also enhances the overall quality of work.

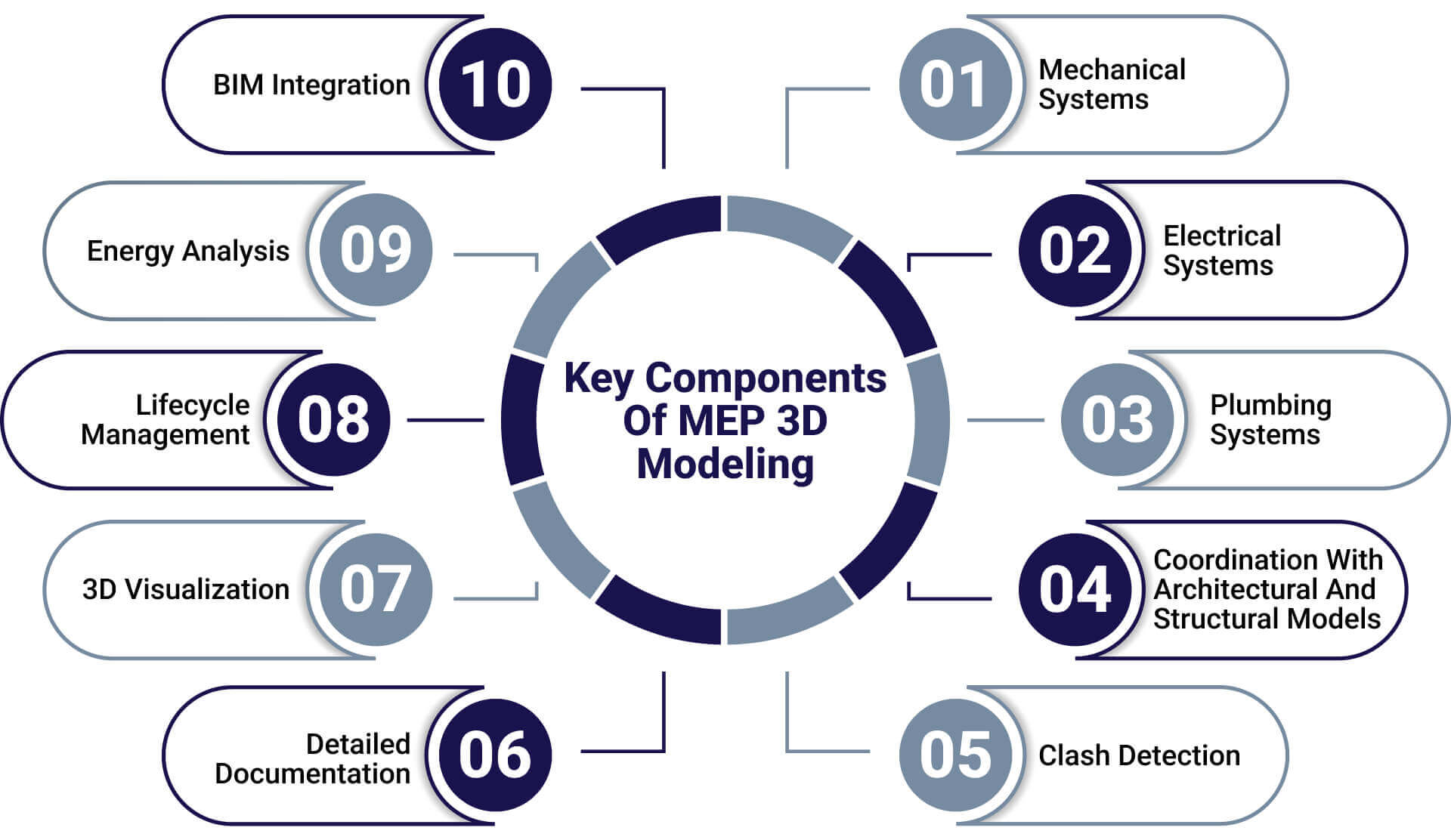

Key Components of MEP 3D Modeling

1. Mechanical Systems

MEP 3D Modeling focuses on HVAC systems, including duct design for efficient air distribution and temperature control. Integrating air handling units is essential for conditioning and circulating air, while chillers and boilers are designed to meet specific building needs. By leveraging mechanical 3D modeling, engineers can visualize layouts, assess performance, and optimize energy efficiency, ultimately enhancing comfort and sustainability in the built environment.

2. Electrical Systems

Electrical systems are a crucial aspect of MEP 3D modeling services, ensuring a building’s electrical infrastructure operates effectively. This process includes planning conduit layouts to minimize interference, designing lighting fixtures for optimal illumination and energy efficiency, and creating power distribution systems to deliver electricity throughout the building safely. A detailed 3D model facilitates early identification of potential issues, leading to smoother installations and compliance with safety standards.

3. Plumbing Systems

Plumbing systems are a vital part of Mechanical 3D modeling, focusing on efficient water delivery and waste removal in buildings. This involves designing water supply layouts for fixtures like sinks and toilets, as well as drainage systems to prevent clogs. Accurate plumbing modeling through MEP BIM modeling services ensures optimal fixture placement and compliance with local codes, ultimately reducing costly rework and creating a reliable plumbing system.

4. Coordination with Architectural and Structural Models

A key benefit of MEP 3D Modeling Services is effective coordination with architectural and structural designs. This MEP coordination enables crucial clash detection, allowing teams to identify conflicts between MEP components and other building systems before construction. This integration streamlines installation and minimizes delays, reducing costly on-site modifications and contributing to a smoother construction process and successful outcomes through MEP BIM modeling.

5. Clash Detection

MEP clash detection is a crucial step in the 3D modeling process that boosts project efficiency. By using advanced software tools, engineers can automatically identify conflicts between MEP systems and structural elements, like those in MEP BIM Modeling Services. This early detection allows teams to collaboratively resolve issues before they escalate, saving time and resources.

6. Detailed Documentation

MEP documentation is crucial for successful construction projects, producing accurate drawings that outline all MEP components and helping teams understand system layouts and specifications. It offers clear guidelines for material selection and installation, ensuring alignment among teams. By providing easy access to this information, MEP documentation promotes transparency and accountability, streamlining communication and minimizing misunderstandings during construction.

7. 3D Visualization

The power of 3D visualization in MEP modeling is invaluable, creating realistic renderings that enhance presentations and stakeholder reviews. This visual clarity improves communication among architects, engineers, and clients, facilitating discussions about complex systems. By visualizing intricate designs, all parties align their understanding, reducing misunderstandings and fostering collaboration.

8. Lifecycle Management

MEP 3D models are crucial for lifecycle management, serving as valuable tools for maintenance and upgrades. They generate as-built documentation that accurately reflects installed systems, providing facility managers with reliable references. This detailed information supports effective planning for maintenance and renovations, ensuring that interventions are based on current data.

9. Energy Analysis

Energy efficiency is increasingly important in construction, and MEP 3D modeling plays a key role in addressing this through analytical methods. Simulations assess the energy performance of HVAC and electrical systems, allowing teams to identify inefficiencies early. Additionally, MEP modeling aids in sustainability assessments, pinpointing opportunities for renewable energy integration and reduced consumption.

10. BIM Integration

MEP 3D modeling integrates with BIM practices to improve the construction process by fostering collaboration among architects, engineers, and contractors. A centralized digital model allows teams to easily update and access critical information, enhancing communication and reducing errors. This streamlined workflow increases efficiency, supports better decision-making, and leads to more successful project outcomes, ultimately transforming teamwork and facilitating a more coordinated construction process.

Conclusion

In the current construction environment, the MEP 3D modeling service is crucial because it offers accurate visualizations that improve stakeholder collaboration and accuracy. Its advantages—such as better coordination, cost-effectiveness, and efficient lifecycle management—reduce mistakes and guarantee adherence to building codes. This method minimizes delays in the construction process by integrating MEP systems with structural and architectural designs.

Furthermore, MEP 3D modeling has been identified as essential for designing sustainable, energy-efficient buildings due to the emphasis on sustainability and energy analysis. In the end, using these cutting-edge methods improves project results and produces resilient, visually appealing, and functional structures.

FAQs on MEP 3D Modeling

1. What are the main components of MEP 3D Modeling?

The main components include:

- Mechanical Systems: Heating, ventilation, air conditioning (HVAC), and fire protection systems.

- Electrical Systems: Wiring, lighting, and power distribution.

- Plumbing Systems: Water supply, drainage, and gas piping.

2. How does MEP 3D Modeling integrate with BIM?

MEP is a subset of Building Information Modeling (BIM), which encompasses the overall digital representation of a building. While BIM covers all aspects of a construction project, MEP focuses specifically on the design and installation of mechanical, electrical, and plumbing systems within that framework.

3. What technologies are used in MEP 3D Modeling?

Common technologies include software like Autodesk Revit for creating detailed models and laser scanning for accurate as-built surveys. These tools help in visualizing complex systems and ensuring precise measurements.

4. How does MEP 3D Modeling improve project collaboration?

MEP 3D Modeling fosters collaboration by providing a shared visual platform for architects, engineers, and contractors. This transparency allows all parties to understand the project better, facilitates communication, and helps in making informed decisions early in the process.

5. How does MEP 3D Modeling contribute to sustainability in construction?

By allowing for precise planning and optimization of mechanical, electrical, and plumbing systems, MEP 3D Modeling helps reduce energy consumption and waste. It enables designers to incorporate energy-efficient systems and renewable energy sources more effectively, contributing to greener building practices.

6. How does MEP 3D Modeling contribute to the development of digital twins?

MEP 3D Models serve as a foundation for creating digital twins of buildings. Digital twins are virtual representations of physical assets that incorporate real-time data from sensors and other sources. By integrating MEP 3D Models with sensor data, facility managers can monitor and optimize building performance, predict maintenance needs, and make data-driven decisions.