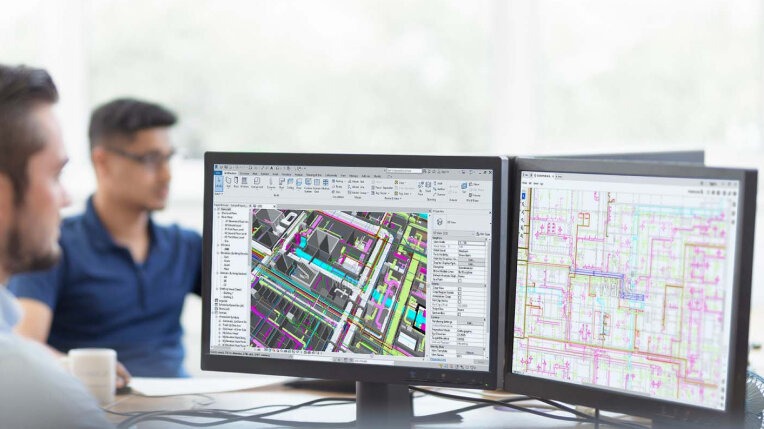

The process of modular construction includes transporting and assembling factory-built building modules on location. Many rooms with a regulated environment and sizeable mechanical, electrical, and plumbing system components are generally included in these projects. MEP system coordination and fabrication have always been complex. By specifying component positions in packed spaces and adhering to design and operating constraints, BIM software can assist in overcoming these difficulties.

When there are fewer parties involved in a project, MEP coordination tasks are prioritized and done sequentially, and 3D BIM models are developed to generate 2D coordinated drawings for submission, the construction process will move more quickly. This would result in less conflict and clashes on the construction site and a smoother, quicker flow of building and installing the appropriate components.

Adoption of BIM methodology for MEP coordination

Building processes can be accelerated by the use of 3D BIM models and by lowering the number of stakeholders involved in the MEP coordination process. By improving BIM design coordination management, this solution enables services to better comprehend project needs, resulting in more seamless installation and construction. Coordination between the mechanical, electrical, and plumbing systems can be quite laborious and time-consuming. It makes up between 40% and 60% of the project. This is a critical step in the off-site modular building process since, at the modelling stage, all three disciplines should be informed of the precise location of the intended installation. Utilizing BIM software technology, the successful technique entails the coordination, documentation, and manufacture of MEP systems in modular structures.

The capacity to produce digital models that can provide a virtual construction solution where the design (3-D), schedule (4-D), cost (5-D) and life-cycle analysis (6-D) may be integrated is a benefit of employing the BIM method. The following discussion covers the potential innovations and enhancements for each modular building dimension.

3-D (Design Modeling)

Projects involving modular construction benefit from the BIM method because it fosters cooperation and communication among all project participants. It enables the design of building modules’ MEP fixtures, outside envelope and interior finishing for use in construction documents and quick prototypes. Before fabrication and installation, conflicts, interferences, and collisions between MEP systems can be found by digitally modelling each component of the building or facility in the model.

4-D (Scheduling Information)

The development of 4D Scheduling is made easier by the integration of 3-D modelling and scheduling information in project design and construction, enabling precise construction and installation process sequences for improved site planning. All project stakeholders receive this information, ensuring that contractors are ready on time. When MEP components are prefabricated concurrently and installed quickly, just-in-time delivery is made possible by scheduling in the manufacturing sector.

5-D (Cost Management)

For each building module, cost estimation in BIM enables the automatic development and adjustment of cost estimates, material quantities, and pricing. Before the fabrication of MEP components and their construction, BIM enables accurate quantity estimation. It also enables the application of the materials cost and installation productivity rate to each system component utilising related data fields. For project teams, this new dimension opens up a wide range of opportunities, including cost tracking in modular construction.

6-D (Life-Cycle Analysis)

This dimension is centred on creating, maintaining, and managing modular structures that are economical with resources, ecologically friendly, cost-effective, and safe for all occupants. It enables interactive analysis of sustainable materials, site assessment, energy efficiency, green materials, indoor environmental quality sustainable job site operations, and building operations, thereby enhancing operational management after project completion and enhancing sustainability.

Technologies to enhance BIM MEP coordination

- Revit API: Application Programming Interfaces (APIs) and visual programming have helped BIM technology advance by minimising manual effort. The AutoRoute Add-In feature is used by MEP engineers to automate rule-based routing, increasing coordinating process productivity. This leads to a more organised design process, fewer conflicts and coordination meetings.

- Cloud Computing Interface: As it can identify conflicts before contractors install services, BIM MEP coordination is essential throughout the design phase. BIM provides clash detection and clarification reports, thus cloud computing interfaces have the added benefit of combining 2D drawings, maintaining 3D BIM models, facilitating cost-effective cooperation, and improving computational capacity.

- Clash Detection: Based on user preferences, Naviswork software is used in BIM coordination to merge models and find incompatibilities. Clash avoidance, improved detection, and filtering are methods. Critical geographical relations for clash management are identified using Component Dependent Network (CDN) approaches, which also produce algorithms, develop a CDN, and store it in a database

Conclusion

By streamlining planning, design, shop drawings, manufacture, and construction, BIM technology encourages multidisciplinary collaboration in building projects. Early on in the design phase, it supports the identification of physical issues to hasten their resolution. For design coordination, walk-through animation, and collision detection, BIM models work well, especially in modular construction projects that demand intensive collaboration, particularly for MEP systems. Modular building technologies are becoming more inviting as a result of this integration, which lessens the need for paper blueprints and specifications.