BIM For Wastewater Treatment Plant

About Project

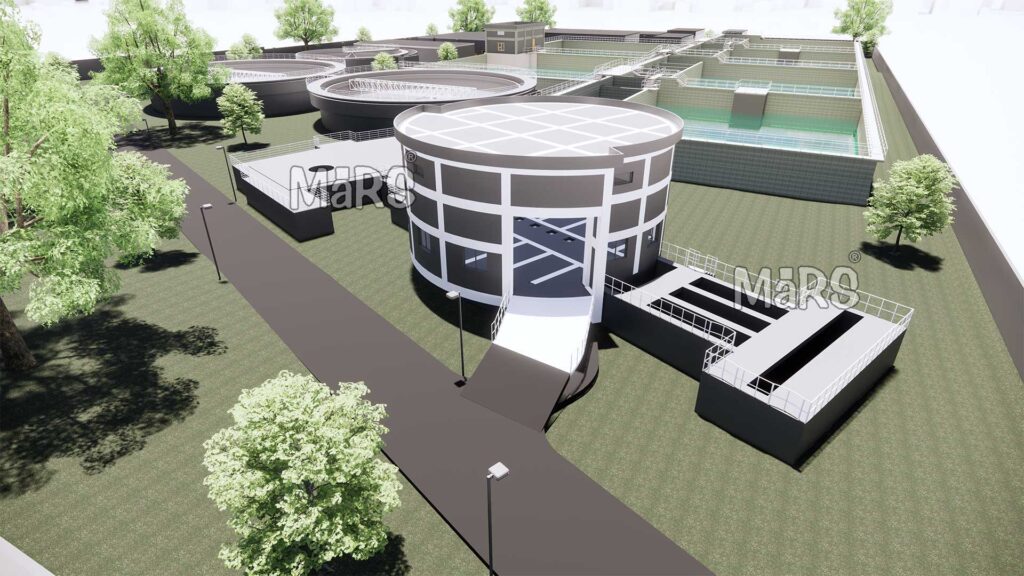

MaRS BIM Solutions executed a groundbreaking BIM project for a 30 MLD CETP (Common Effluent Treatment Plant) in Ahmedabad, India. This initiative aimed to control illegal water pollution in the Sabarmati River, caused by the discharge of untreated effluents from textile units.

The project, with a cost of approximately $21 million USD, addressed the critical issue of the municipal pipeline’s insufficient capacity to handle the daily 30 MLD of untreated effluent. The new CETP facility links all industrial units to a modern pipeline system, ensuring that untreated wastewater is properly processed and preventing unauthorized discharges into the river.

Our role involved designing and developing the BIM model, which facilitated detailed planning and seamless integration of various complex systems within the plant. We employed our expertise in 3D BIM modeling, 4D scheduling, 5D cost estimation, clash detection, and customized solutions for construction workflow monitoring to deliver this complex project efficiently and cost-effectively.

Additionally, our BIM solutions incorporated performance and environmental monitoring systems within the digital model. This integration provided highly detailed visualizations and real-time data analysis, crucial for leak detection, predictive maintenance, and data-driven decision-making. By strategically placing sensors throughout the plant, we ensured constant data collection and transmission, reflecting real-time conditions in the digital model.

The BIM implementation significantly enhanced the project’s efficiency, reduced costs, and improved environmental compliance. Completed within six months following the three-year construction phase, our BIM solutions played a vital role in eliminating illegal effluent discharges into the Sabarmati River, showcasing the transformative impact of digital technology on environmental sustainability.

Our Client’s Challenge

- The previously alleged illegal discharge of untreated effluents into the Sabarmati River by certain textiles industrial units in the surrounding area was a significant environmental concern.

- 732 units were awaiting the operationalization of their 30 MLD CETP, with efforts underway to streamline the process.

- The municipal pipeline lacked the capacity to carry around 30 MLD per day untreated effluent, leading to unauthorized discharges.

- The client needed a way to coordinate effectively among multiple stakeholders, including engineers, contractors, and regulatory bodies.

- There was a need for real-time monitoring and data-driven decision-making to manage plant operations effectively.

- The client faced challenges in integrating various complex systems within the wastewater treatment facility.

- Addressing public and governmental pressure to resolve the pollution issue promptly and sustainably was critical.

- Identifying and mitigating potential issues during the construction and operational phases to prevent costly delays and rework was essential.

Our Approach and Solution

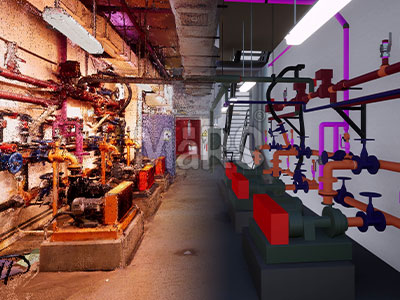

- Advanced BIM software tools, such as Autodesk Revit, AutoCAD, and Navisworks, were used to create precise models and conduct clash detection, identifying and resolving any conflicts before construction began.

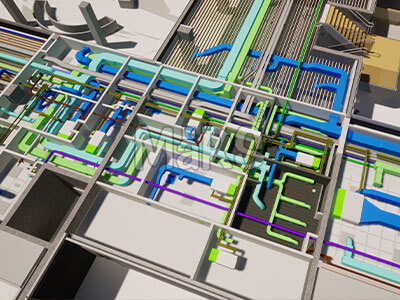

- Our team developed a comprehensive 3D BIM model, incorporating all critical structural, mechanical, electrical, and plumbing components to ensure seamless integration and functionality.

- We provided 4D scheduling using Bentley Synchro 4D software, which integrated time-related data into the BIM model, allowing for detailed construction sequencing and effective project timeline management.

- A 5D cost estimation feature was integrated into the BIM model, enabling accurate budgeting and cost tracking throughout the project lifecycle.

- We established a centralized digital platform for real-time collaboration and communication among all stakeholders, ensuring that everyone had access to the latest project information and updates.

- We worked closely with regulatory bodies to ensure all necessary approvals were obtained promptly, using the detailed BIM model to facilitate the review process.

- Customized solutions for construction workflow monitoring were implemented, enabling real-time tracking and management of project progress, ensuring timely and efficient execution.

- Sensors were strategically placed throughout the plant to collect and transmit real-time data, which was integrated into the BIM model for continuous monitoring and analysis.

- Predictive analytics were used to anticipate maintenance needs, reducing downtime and extending the lifespan of the facility's components.

- Detailed visualizations and virtual walkthroughs of the BIM model were provided to the client, allowing for better understanding and planning of the project.

- Post-construction, we provided a Digital Twin of the CETP, integrating performance monitoring systems for ongoing operation and maintenance, ensuring the plant operates efficiently and sustainably.

- Our approach included continuous feedback loops, where data from the construction site was regularly updated in the BIM model, ensuring that the model remained accurate and reflective of the actual conditions.

ESG Impact

We established a comprehensive dashboard for environmental monitoring, covering air quality, treated wastewater, soil quality, and noise levels. Using our digital twin technology, the environment, health, and safety department coordinates all monitoring programs, with data regularly submitted to statutory agencies every six months.

Several manufacturing units have adopted zero liquid discharge technology, guided by insights from the Digital Twin. This technology minimizes water consumption and eliminates effluent discharge, aligning with ESG principles and demonstrating environmental responsibility.

The successful operation of the CETP benefits the local community by reducing pollution, enhancing the well-being of residents in surrounding area.

Key environmental improvements include:

- pH of untreated effluent reduced from 9.5 to 7.1

- Oil & Grease levels reduced from 22.5 mg/l to below detection limits

- COD levels decreased from 1457 mg/l to 146 mg/l through treatment stages

- TSS dropped from 312 mg/l to below detection limits

- NH3-N reduced from 30 mg/l to below detection limits

These improvements were verified by the government, highlighting the CETP’s effectiveness and commitment to sustainability.

Achievement

Looking for BIM Services in India?

MaRS BIM Solutions offers specialized BIM services in India focusing on precision and efficiency in 3D modeling, clash detection, and project management. Reach out to us to support your next project.