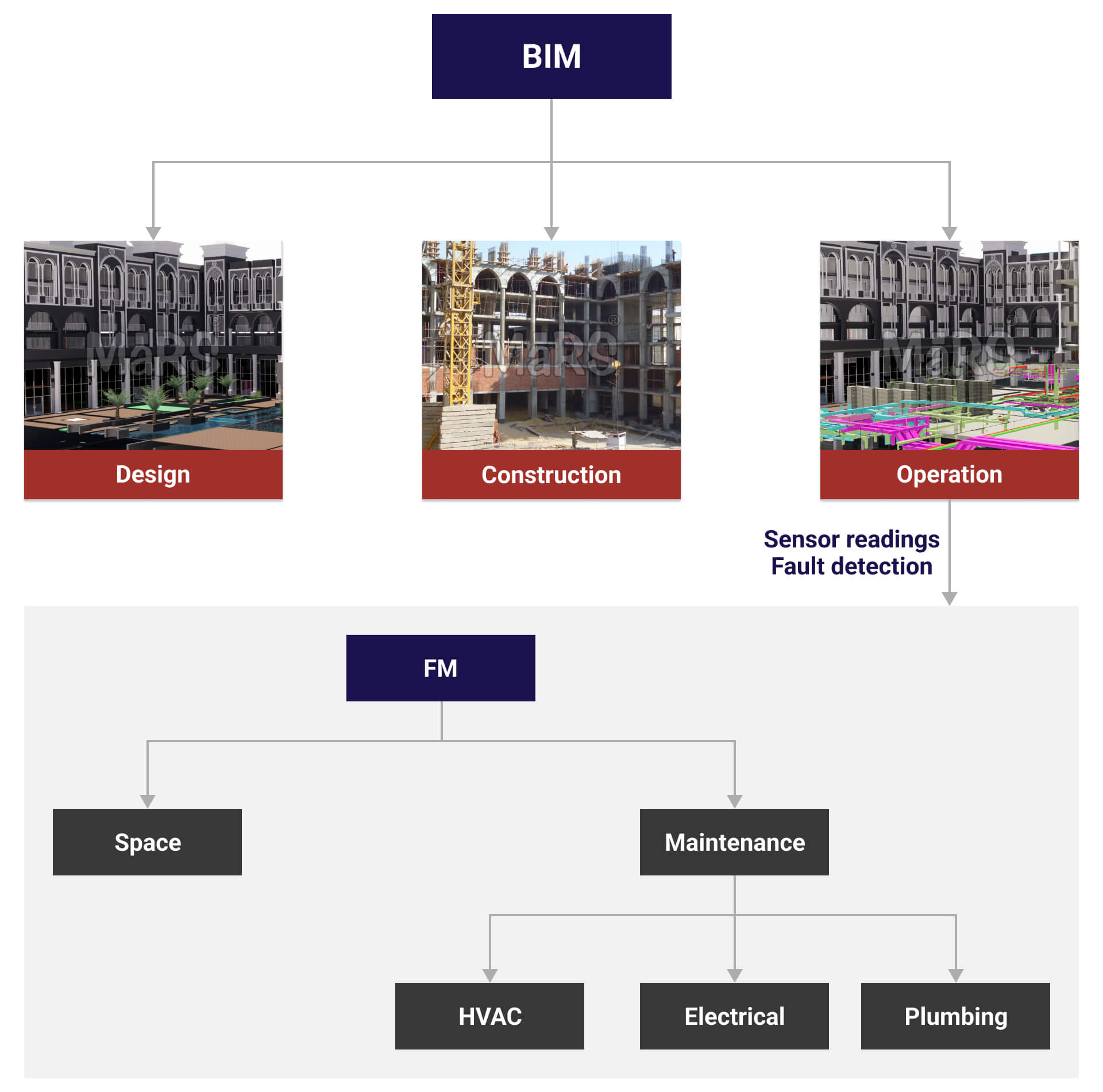

BIM is disruptive which is useful for the entire duration of a building’s life cycle because it represents its physical and functional characteristics in digital form. These days, modern buildings have complex MEP systems that include mechanical, electrical and plumbing aspects. This means we need to maintain them to prevent failures caused by poor coordination between these systems among other things. In this regard, BIM provides a strong mechanism for detecting faults within MEP systems about which there are many things to consider before they become costly breakdowns. The present article examines how BIM improves MEP system maintenance through enhanced feature detection and diagnosis; leading to efficient buildings with reduced operational costs.

Understanding MEP System Challenges

Modern buildings are more often than not highly dependent on MEP systems which are networks of complicated webbings that in turn provide fundamental services like heating, ventilation, air conditioning (HVAC), lighting, power distribution, plumbing and fire protection. These systems are usually interlinked making them very complicated and thereby prone to a wide spectrum of failures. Some common problems include:

- HVAC: Refrigerant leakages, defective sensors, fan or motor breakdowns, leaks in ductwork and control-system errors.

- Electrical: Faulty wiring; circuit breaker tripping; transformer breakdowns; lighting perversions and power outages.

- Plumbing: Leaking pipes; blocked drains: pump failures; water heater problems and sewage back-ups.

Traditionally these systems have been maintained with a reactive approach where repairs are done after faults have occurred leading to disruption. This approach comes with several disadvantages including the following:

- Unplanned Downtime: Unexpected system failures have been known to bring about disruption in the operations of a building and hazards for safety.

- High Repair Costs: Emergency repairs tend to cost more than planned maintenance because of the urgency and necessity for specialized engineers.

- Reduced Equipment Lifespan: Wear and tear on equipment can be hastened by constant breakdowns which lead to early replacement needs and shorten its lifespan.

- Energy Inefficiency: Unnoticed faults lead to energy wastages that increase operational costs as well as the environmental footprint of a building.

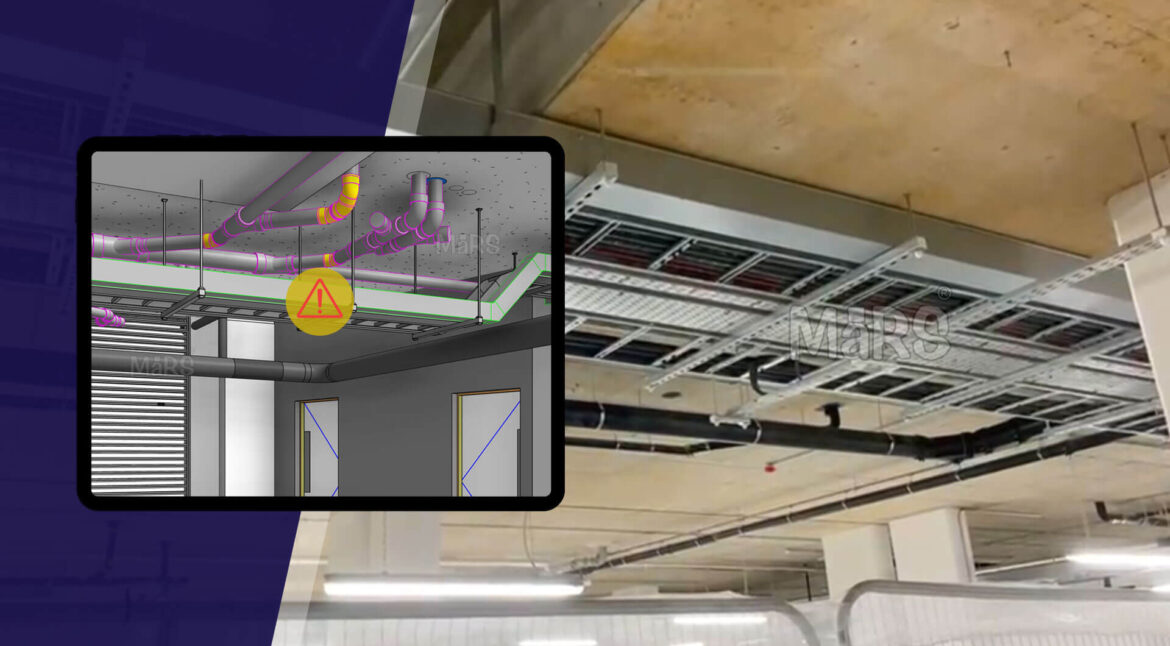

Modern complex structures can no longer sustain a reactive maintenance model. As such, a proactive approach that can detect and diagnose faults at their early stage is necessary. Towards this end, BIM comes in handy with its transformative solution for MEP system maintenance. BIM brings an evolution in MEP coordination by integrating advanced 3D modeling and real-time data sharing.

How BIM Enhances MEP Fault Detection?

The accuracy and efficiency of a project is improved throughout its lifecycle by using BIM-based Revit MEP modeling instead of traditional methods, which often result in errors and inefficiencies.

| Technique | Description | Potential Issues Detected | Example |

| Data-Rich Models | Centralized repository of detailed 3D geometry, properties, and relationships of MEP components. | Design errors, missing components, incorrect specifications | A pipe with the wrong diameter is identified before installation. |

| Clash Detection | Automatic identification of spatial conflicts between MEP components | Pipe collisions, ductwork interference with structural elements | A duct is rerouted in the design phase to avoid clashing with a beam. |

| Energy Analysis | Simulation of energy consumption of MEP systems to identify inefficiencies. | Oversized equipment, poor insulation, inefficient control strategies. | A building’s HVAC system is optimized to reduce energy use by 15% |

| Computational Fluid Dynamics (CFD) | Modeling of airflow and pressure distribution in HVAC systems | Unbalanced airflow, ductwork leaks, poor air mixing | A poorly designed diffuser is identified and replaced to improve air distribution |

| Sensor Integration | Connection of BIM with real-time sensor data for continuous monitoring | Abnormal temperature readings, pump failures, electrical overloads | A leak in a chilled water pipe is detected due to a sudden pressure drop |

BIM in MEP System Diagnostics

Diagnostics go further than fault detection by identifying the cause of faults. Several ways can be used to achieve this; however, BIM plays a prominent role in this. It not only provides a lot of information for analysis and troubleshooting but also acts as a platform for communication among the parties (clients, construction team, engineers) involved.

Root Cause Analysis

BIM enables instant identification of root causes whenever some error is found. It saves the time required to identify any given problem through the trial-and-error method since within a single model all relationships between components are visible at once.

Predictive Maintenance

One can use BIM Services for predictive maintenance to detect possible issues that can result in equipment breakdowns. The interpretation process involves information from sensors stored historically besides maintaining records along with the algorithms that predict the time of failure of equipment which are incorporated in the BIM model that possess complete details.

Remote Diagnostics

MEP system problems can be diagnosed with no need for technicians to be physically present using MEP BIM Services integrated with Building Information Modeling (BIM). There are times when engineers have to check sensor data remotely or even study their performance while at work and highlight any possible challenges they might observe.

Buildings at distant locations benefit the most from this kind of solution as on-site access may be challenging. In addition, response time improves since experts can seek advice immediately instead of traveling.

Conclusion

MEP system fault detection and diagnostics have never been the same since BIM. It is imperative to note that through BIM, a comprehensive data-rich platform for analyzing and monitoring system performance, a transition from reactive to proactive maintenance can be made thus reaping myriad benefits including lower costs of operation, higher availability and better energy utilization.

It should be noted that there are challenges. Costly investments in software, hardware and training form part of the implementation process of BIM. Moreover, data quality and integration need to be addressed as well. However, with ongoing advancements in BIM technology coupled with the increasing complexities associated with MEP systems in modern structures, it is clear that BIM is not a trend but an essential tool for future building maintenance programs.