BIM-Based Digital Fabrication

Take your construction project to the next level with our BIM-based digital fabrication services. At MaRS BIM Solutions, we use smart technology and automation to deliver precise, high-quality components faster and more efficiently.

BIM-Based Digital Fabrication Services

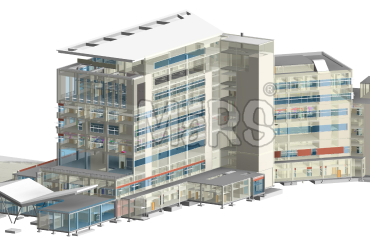

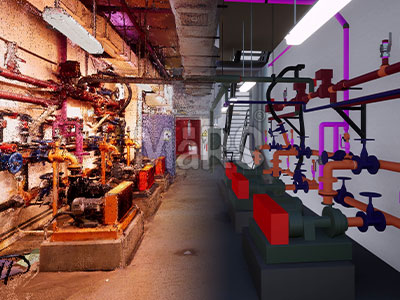

At MaRS BIM Solutions, we bridge the gap between design and construction through cutting-edge BIM-based digital fabrication. This innovative approach leverages BIM to create highly accurate, data-rich models that are directly translated into fabrication-ready components. By using advanced technology, we streamline the manufacturing process, ensuring precision, reducing waste, and accelerating project timelines.

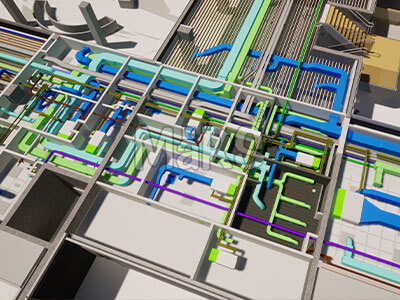

BIM-based digital fabrication not only improves the overall efficiency of construction projects but also allows for greater control over the entire process. The 3D models we create contain embedded data, such as material specifications, structural details, and installation requirements. This ensures that every component is fabricated to exact standards, eliminating errors commonly associated with manual processes. Whether it’s prefabricating structural elements or producing intricate MEP systems, the precision and consistency achieved through BIM are unmatched.

As construction moves towards greater sustainability and innovation, BIM-based digital fabrication has become a game-changer. The ability to design, analyze, and manufacture building components in a controlled environment reduces material waste, optimizes resource usage, and limits on-site disruptions. By embracing this modern approach, MaRS BIM Solutions helps clients realize the full potential of digital construction, providing them with reliable, cost-effective, and environmentally friendly solutions.

By implementing BIM-based digital fabrication, projects can shift significant portions of the construction process off-site to controlled environments. This prefabrication approach minimizes the risks typically encountered on-site, such as weather delays and human error, while allowing for simultaneous off-site production and on-site preparation. This parallel workflow not only saves time but also enhances safety by reducing the need for extensive on-site labor and heavy machinery.

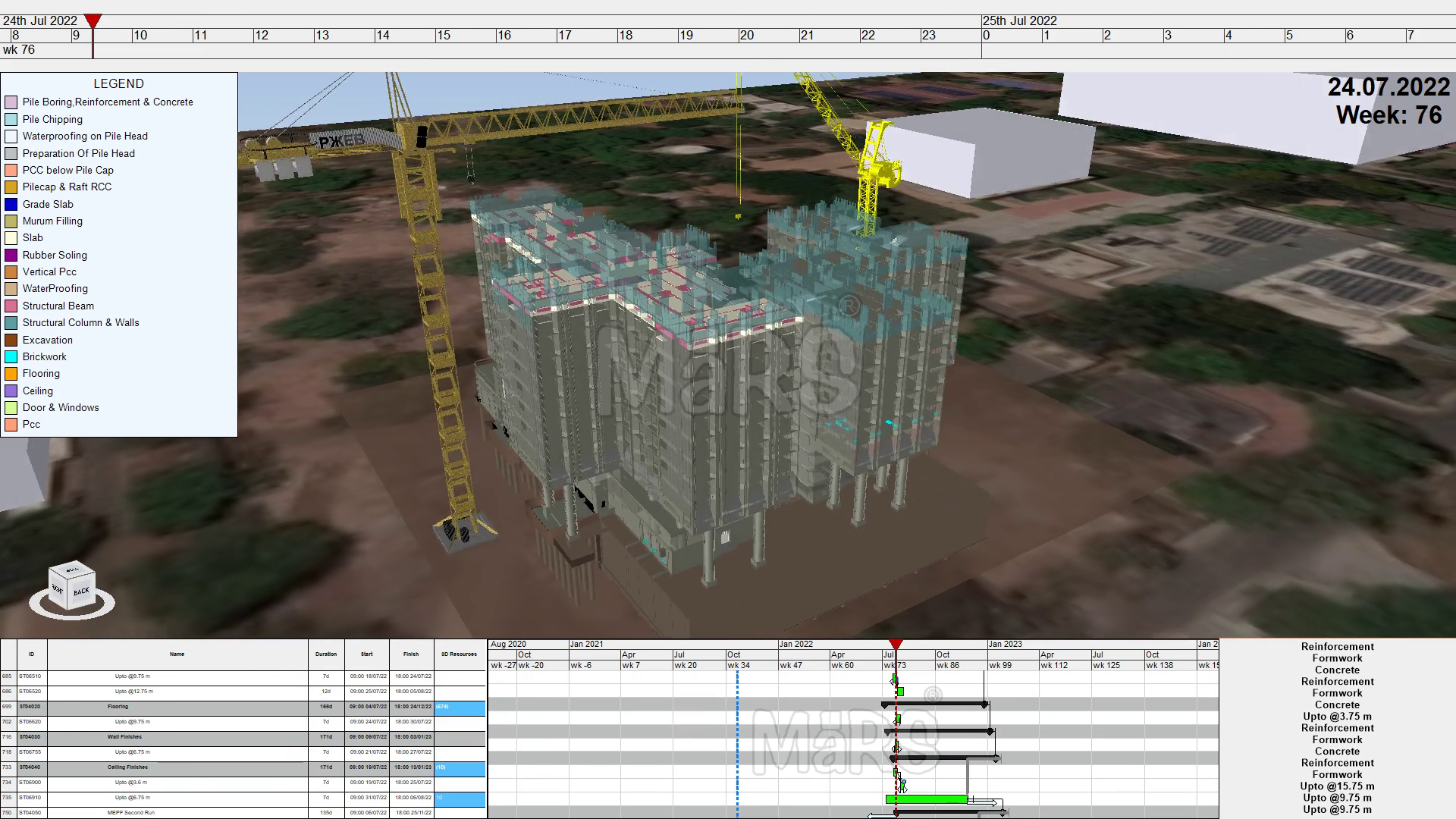

Our BIM-Based Digital Fabrication Process

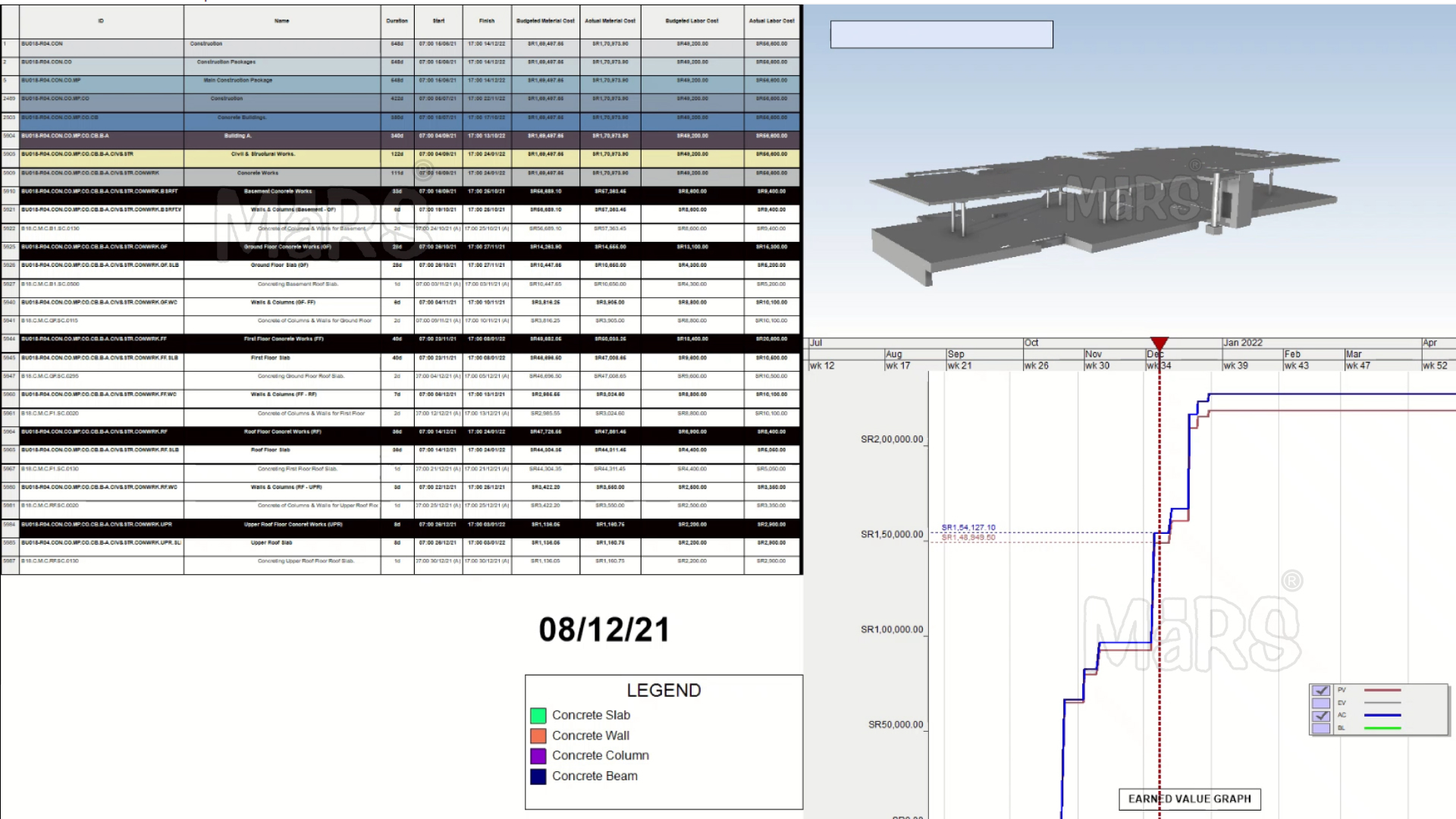

Design and Modeling

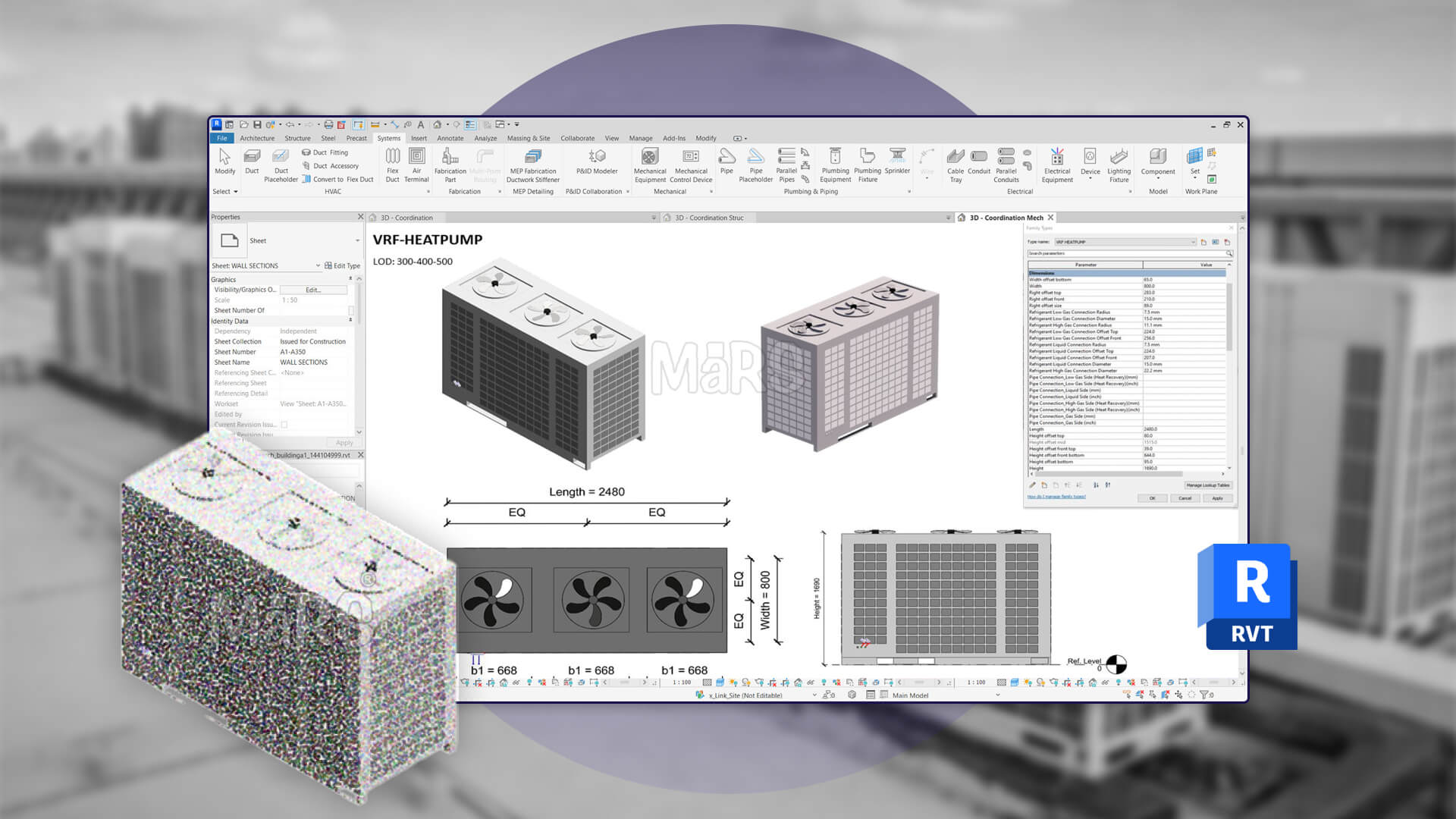

The foundation of our digital fabrication process begins with detailed 3D BIM models. These models not only capture the geometry but also embed critical data, making them fabrication-ready. Our skilled team uses industry-leading software such as Revit and AutoCAD to create precise and detailed models that serve as the blueprint for fabrication.

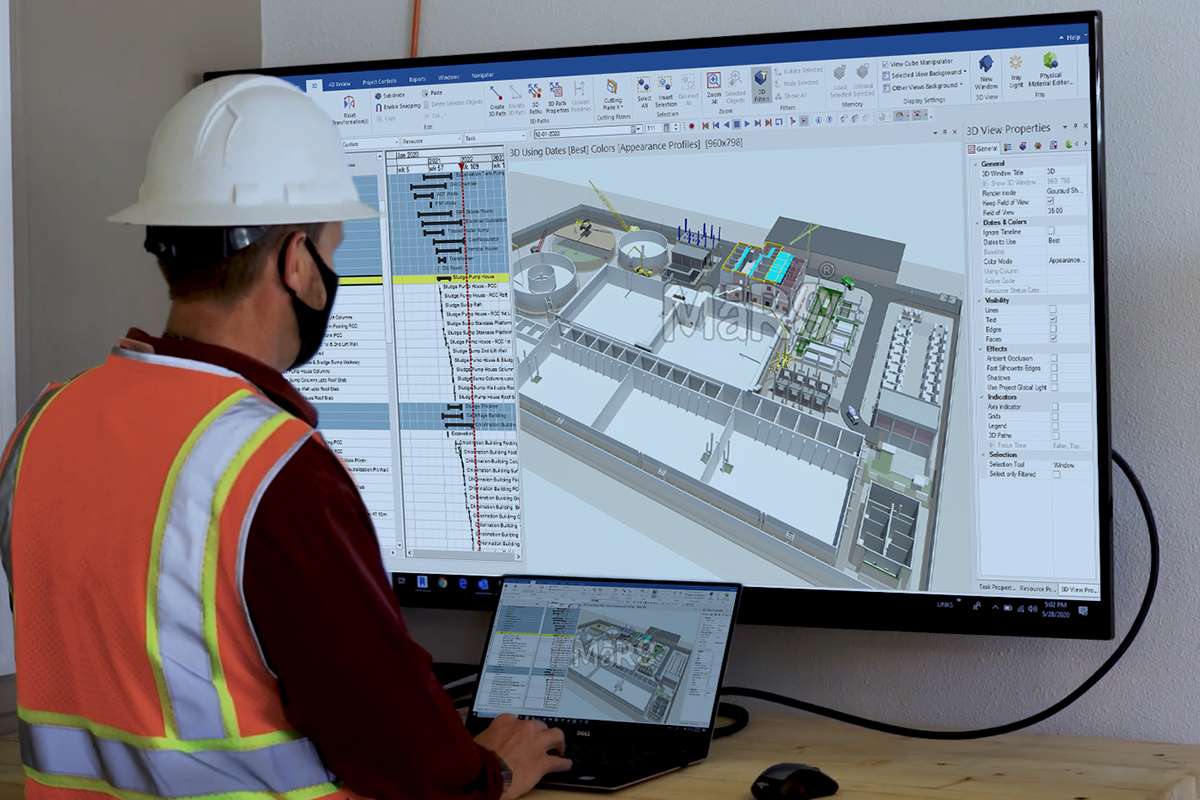

Collaboration and Coordination

Seamless coordination between all project stakeholders is key to successful digital fabrication. At MaRS BIM Solutions, we work closely with architects, engineers, and fabricators to ensure every aspect of the project is well-aligned. By utilizing BIM data, all teams are on the same page, reducing miscommunication and preventing costly on-site errors.

Fabrication and Automation

Once the BIM model is approved, we move to the fabrication stage, where the data is transmitted to CNC machines, robotic arms, and other automated tools. These machines convert the digital designs into physical components, ensuring millimeter-precise fabrication. The automation not only accelerates production but also maintains consistent quality across every component.

Quality Control

We take quality seriously. Each component undergoes rigorous quality checks to ensure that it meets the exact specifications outlined in the BIM model. This guarantees that the fabricated components fit seamlessly on-site, reducing the need for rework and ensuring smooth project execution.

Benefits of BIM-Based Digital Fabrication

Precision and Accuracy

With BIM-based digital fabrication, every element of a project is meticulously planned and modeled before production. This ensures a high degree of precision in the manufacturing process, reducing human errors and guaranteeing that each component fits perfectly during assembly. At MaRS BIM Solutions, our commitment to precision helps reduce project delays and ensures a seamless installation process.

Cost and Time Efficiency

By integrating BIM with digital fabrication, we streamline the entire construction process. Components are fabricated off-site in controlled environments, which reduces on-site labor costs and minimizes project timelines. This method of prefabrication and modular construction ensures that projects are completed faster and more efficiently, without sacrificing quality. Our approach also allows for better budget management by reducing material waste and avoiding costly rework.

Reduced Waste and Sustainability

Sustainability is at the forefront of modern construction, and BIM-based digital fabrication contributes significantly to this goal. The accuracy of BIM models ensures that only the required amount of materials is used, reducing excess waste. Additionally, off-site fabrication reduces the environmental impact by optimizing material use and decreasing transportation needs. By choosing MaRS BIM Solutions, you’re opting for an environmentally responsible approach to construction.

Improved Collaboration

BIM technology fosters real-time collaboration between all stakeholders involved in a project. Architects, engineers, and fabricators work from the same model, allowing for instant updates and coordinated workflows. This level of integration ensures that everyone stays aligned throughout the project lifecycle, reducing errors, enhancing communication, and speeding up decision-making processes.

Technology and Tools We Use

We use cutting-edge technology to make sure our BIM-based digital fabrication process is as accurate and efficient as possible. It all starts with powerful software like Revit, AutoCAD, and Archicad, which help us create detailed 3D models. These models aren’t just visuals—they’re packed with essential information, from material specifications to installation details, that guide the fabrication process. This level of detail allows us to ensure that every component is made precisely to fit the project’s needs, reducing errors and speeding up construction.

Why Choose Us

At MaRS BIM Solutions, we are at the forefront of BIM-based digital fabrication technology. Our team of experts brings years of experience in both BIM modeling and automated fabrication, ensuring that your project is delivered with precision, efficiency, and sustainability in mind. We pride ourselves on our innovative approach to construction, utilizing cutting-edge tools and technologies to produce high-quality results that meet the demands of modern building standards.

Our Latest BIM Projects

Get In Touch

Feel free to reach out to us for any inquiries or to discuss your project needs.