Structural Steel Detailing

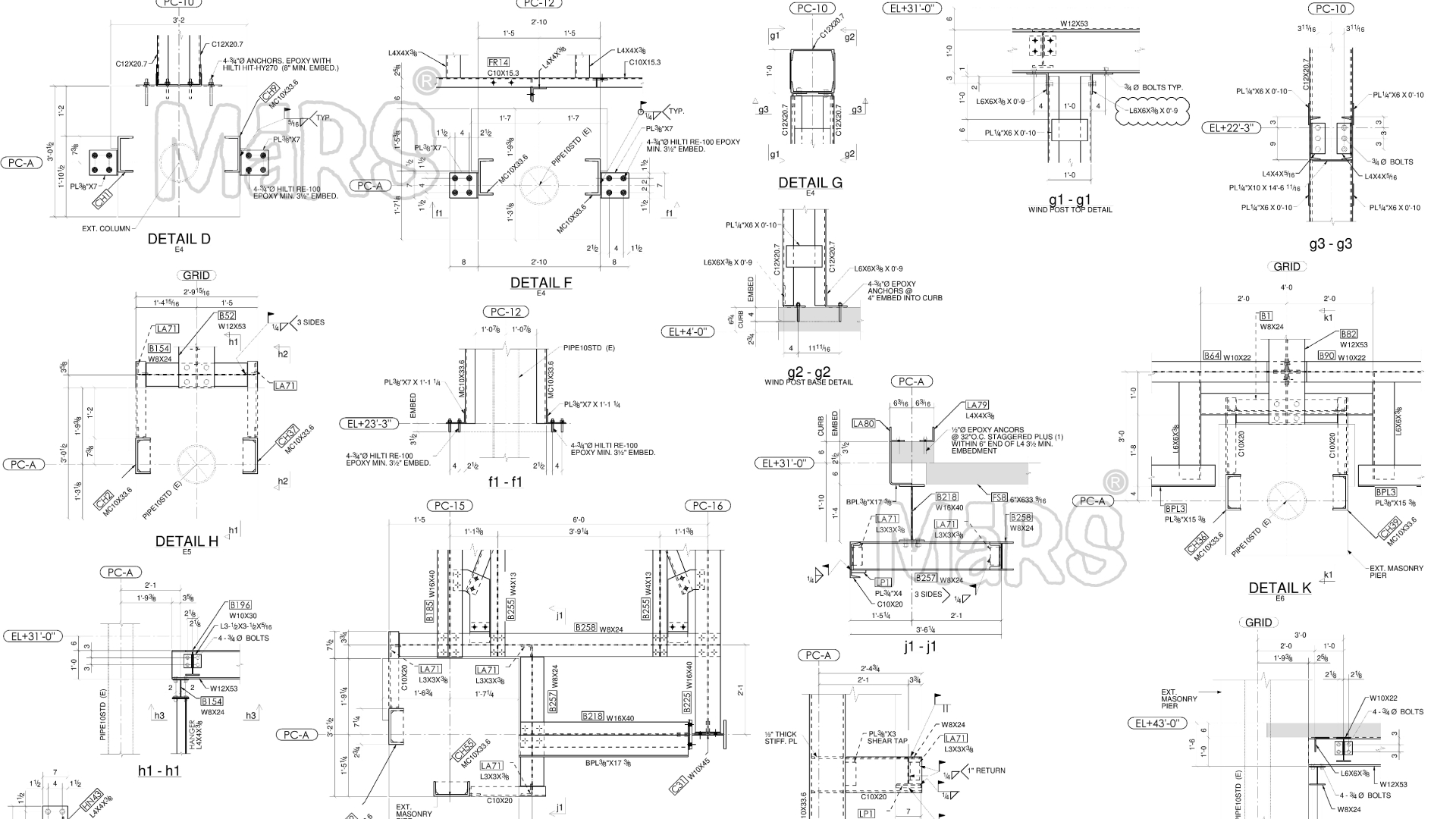

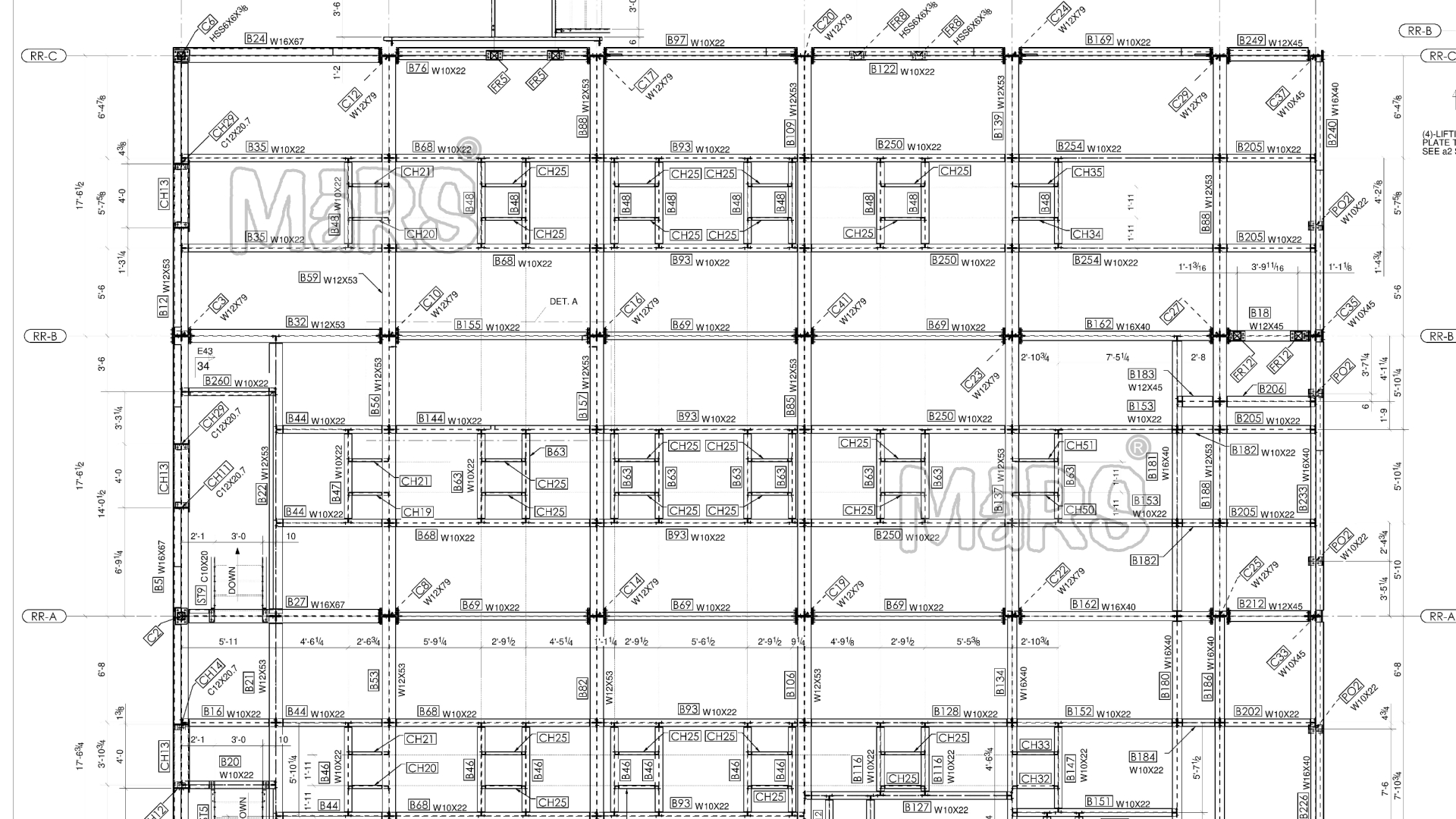

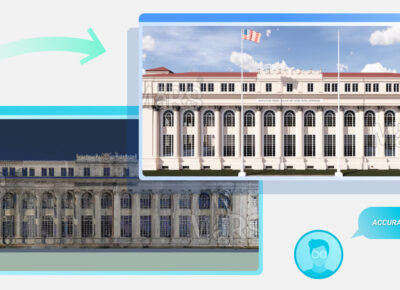

Structural Steel Detailing services offered by us are accurate and data-driven that has informative details of the project. It requires accuracy and precision as needed by fabricators and contractors. The structural drawings involves plans and estimates that makes the project work more reliable and easy to understand.

Structural Steel Detailing Drawings And Modeling

We are the leading structural steel detailing drawings and modeling service provider globally. The company holds a strong team of structural engineers who understand the requirement of the services and provide drawings and modeling services.

The production of shop drawings for a steel fabricator is called steel detailing. For all types of construction projects, there is a need for a steel fabricator in the company. Our structural steel detailing drawings and modeling help share the key areas of the products that help install, manage, and provide the steel framework.

Our core service is to help generate structural steel detailing drawings that help the fabricator understand the overview of the project. Also, it carries further with the use of aggregating the process to cut and weld all necessary steel members together. To streamline the project understanding, our team generate the layout and design of the project with the necessary instruction. The instruction shared facilitated the installation and erection of the steel framework.

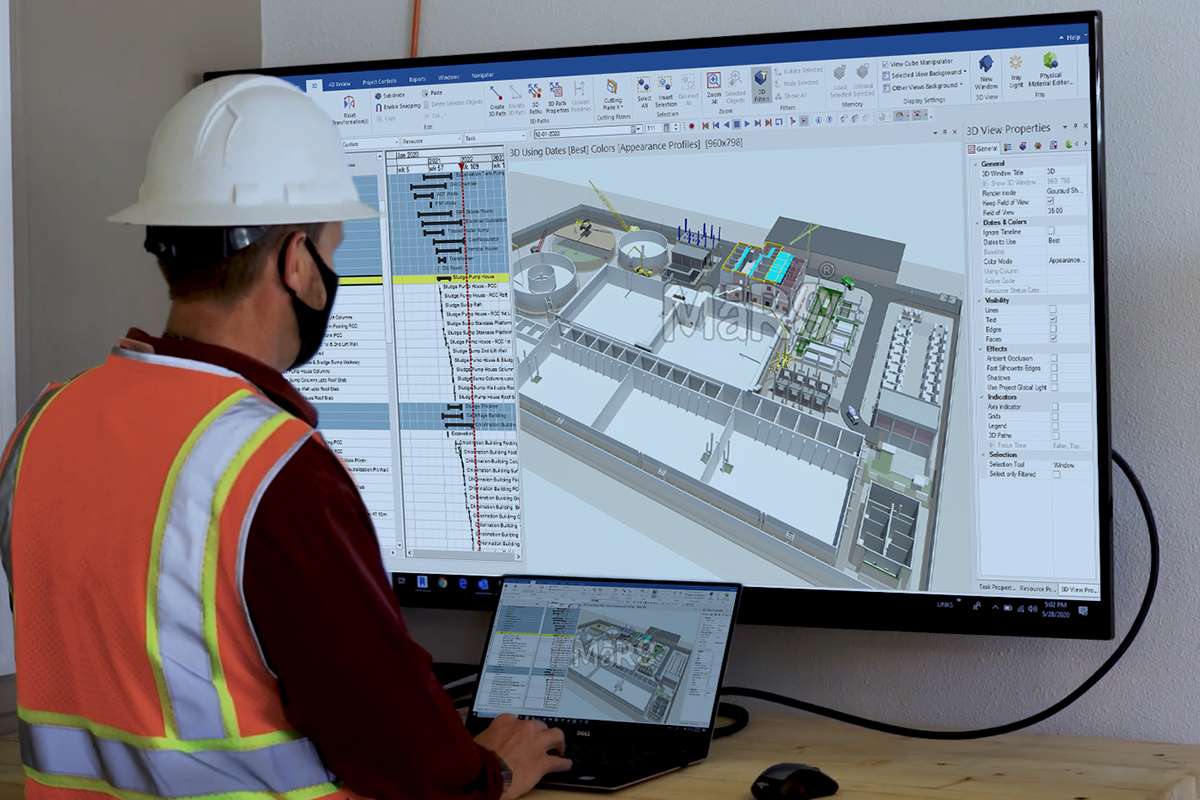

The construction project undergoes multiple staging of work during its complete process. During the construction phase from its start to its end, structural steel detailing drawings and modeling play an important role. To evacuate the detailing and working of the project, the team uses to follow necessary steel detailing codes and standards. The use of this technology is based on the project work during pre and post-staging.

Structural steel detailing work requires 99.9% accuracy and involvement in erection drawings and shop drawings. The team at MaRS BIM prepares the drawings and model to ensure that the structure is safe, secure, and strong.

We deliver the project to our clients with proper measuring, dimensions, and length so that there is no possibility of rework as well as clashes. With experience of over a decade-plus, we assure our clients to deliver them skilled and data-driven steel detailing services that are ideal for the business and project.

Structural Steel Detailing Services We Offer:

Steel Frame Connections

Miscellaneous Steel Detailing

Column Beam Joint Detailing

Footing Design for Steel Columns

Structural Steelwork Detailing

Steel Beam to Wall Connection

2D Drawings for Precast Detailing

3D Steel Detailing

FAQS

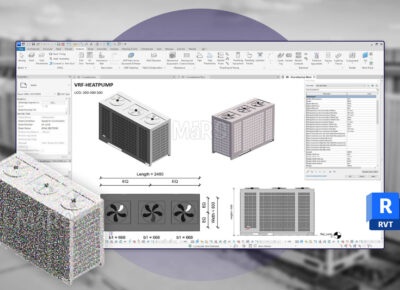

Popular software for structural steel detailing includes Tekla Structures, Autodesk Advance Steel, SDS/2, ProSteel, and StruCAD. These tools enable precise 3D modeling and ensure that all elements fit together accurately during fabrication and construction.

- Shop drawings are detailed plans that steel fabricators use to create steel components. These drawings contain information about dimensions, materials, welding, bolting, and any special instructions needed to produce the structural elements accurately.

- Connection design refers to how steel components are joined, either through welding, bolting, or other methods. In steel detailing, connection designs are carefully calculated to ensure structural integrity. Detailing software like Tekla and SDS/2 can automate connection design based on structural loads and design specifications.

- Erection drawings are detailed instructions that guide the construction team in assembling the steel structure on-site. These drawings show the exact location of each steel component and outline the sequence in which they should be assembled.

- A steel detailer plays a critical role in ensuring the accuracy and fit of steel components. They work closely with engineers and architects to translate design requirements into detailed drawings that fabricators use. The detailer ensures that the steel components fit together correctly during construction.

- Structural steel detailing must adhere to industry standards and codes like AISC (American Institute of Steel Construction), BS 5950, and Eurocode 3, which dictate the guidelines for steel structure design, fabrication, and installation.

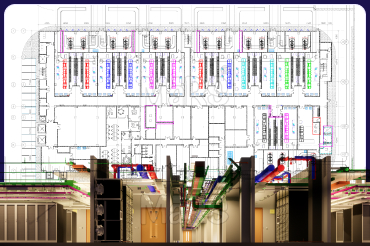

- Yes, modern steel detailing software integrates with BIM (Building Information Modeling) workflows, enabling collaboration between architects, engineers, and fabricators. This integration ensures real-time updates and coordination across disciplines, minimizing clashes and errors.

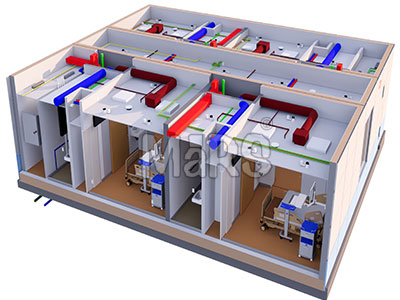

- Clash detection identifies potential conflicts between steel components and other building systems (such as HVAC or electrical). Using 3D modeling software, clashes are detected early in the design phase, allowing adjustments to be made before fabrication and construction begin.

Get In Touch

Feel free to reach out to us for any inquiries or to discuss your project needs.