The process of structural steel detailing services is a tedious job. The level of accuracy is high, and a small mistake can lead to a loss of time, energy, and money. Structural steel detailing is an important as well as a mandatory process. For activities like the manufacturing and construction sector, steel detailing services is a must-have service.

Structural steel detailing and its process is the communications link between the team members and professionals. It is the core responsibility of the members to maintain collectively or individually the level of accuracy in each stage.

For fabricators and contractors, steel detailing services is a key planner. It involves the process of detailed drawings that is a vital part of the project. The detailing includes plans and estimations with a mark-up of tasks and points. Shop Drawings and Erection Drawings are two pillars of drawings.

Let us move further and discuss these two pillars of structural steel detailing.

Shop Drawings

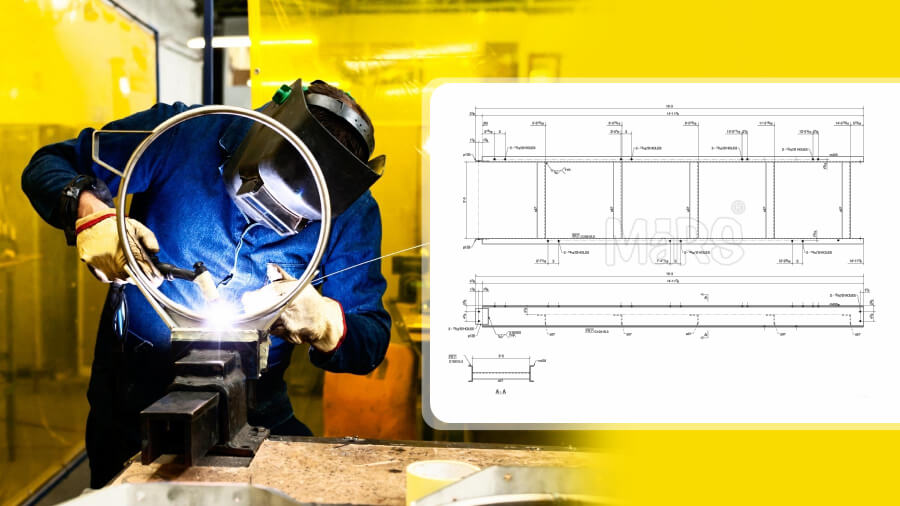

The fabricators undertake shop drawings services, as it specifies the minor information related to the detailing work. It is the process in detailed drawings in which the contractor, fabricator, and the project owners receive the smallest detail of a steel piece or components.

The work of shop drawings includes all fabrication-related information that plays a vital role in structural steel detailing work. These steel fabrication shop drawings submitted have relevancy only to fabrication work. It is not having any details related to the erection and installation of the steel elements.

Erection Drawings

When it comes to portraying dimensioned plans with specification services undertaken is erection drawings. It helps specify the location of the steel component that is within the overall structure. These drawings include all details and specifications related to the positioning of each element required for installation. It continues with the associated fieldwork like installing bolts, wedge anchors, and welding spots.

Steel Detailing Standards

The fabrication work is known to be the most tedious job. To maintain meticulousness it is mandatory to follow steel detailing standards. Here is the list of international standards undertaken in the projects.

- American Institute of Steel Construction (AISC)

- American Welding Society (AWS)

- National Institute of Steel Detailing (NISD)

- Canadian Institute of Steel Construction

- Australian Institute of Steel Construction

- Euro Codes and British Standard Codes

Read also: Why Structural Steel Detailing Is Playing A Vital Role In The Field Of Construction?

Areas of use of Structural Steel Detailing Services

Till today we have understood about steel detailing services along with its standards. The next point of discussion is in which areas this service is appropriated. Let us take a look at some of them.

- Pre-Engineered Building

While working on pre-engineering building projects, the technology used is structural steel detailing services. These are the buildings that are pre-designed and ready to install. Also, the construction of these buildings has wall cladding and a structural roof as the base of the project. - Light Metal Framing

When the project is related to light metal framing work, the engineers use structural detailing services. It is the process that helps design and draft the framing of the model with accuracy and determination. Also, the work undertaken for both residential and commercial projects. Further, the communication level is smoother between the parties as it helps reduce flaws in construction and fabrication. - Aluminum Curtain Walling and Facade:

Structural detailing is a vital element of facade fabrication and aluminum curtain walling. The undertaking of the work is simple in terms of solving complexities and errors. The issues arising during the construction sequence are considered. The necessary process is on a practical basis, not trials and errors base. - Bridges, Towers, and Rails: Structural steel detailing is a noted service for Bridges, Towers, and Rails construction projects. The work and outcome of the service are practical and appropriate with necessary details. Its overall process involves delivering high-end automation work that leads to better project management.

- Evaluating the Project Lifecycle:

Structural detailing services play an important role in large construction projects. It shares the information and data that is beneficial throughout the project. It is the responsibility of the engineer to pass on information about the project to the facility manager and owner. The data pertains to the building’s lifecycle and its managerial outcomes.

Final Words

Structural BIM Modeling is the pillar for construction projects. Without proper understanding and detailing if worked can lead to the process of rework. Thus, the best way to avoid these problems is to opt to detail work with outsourcing companies.