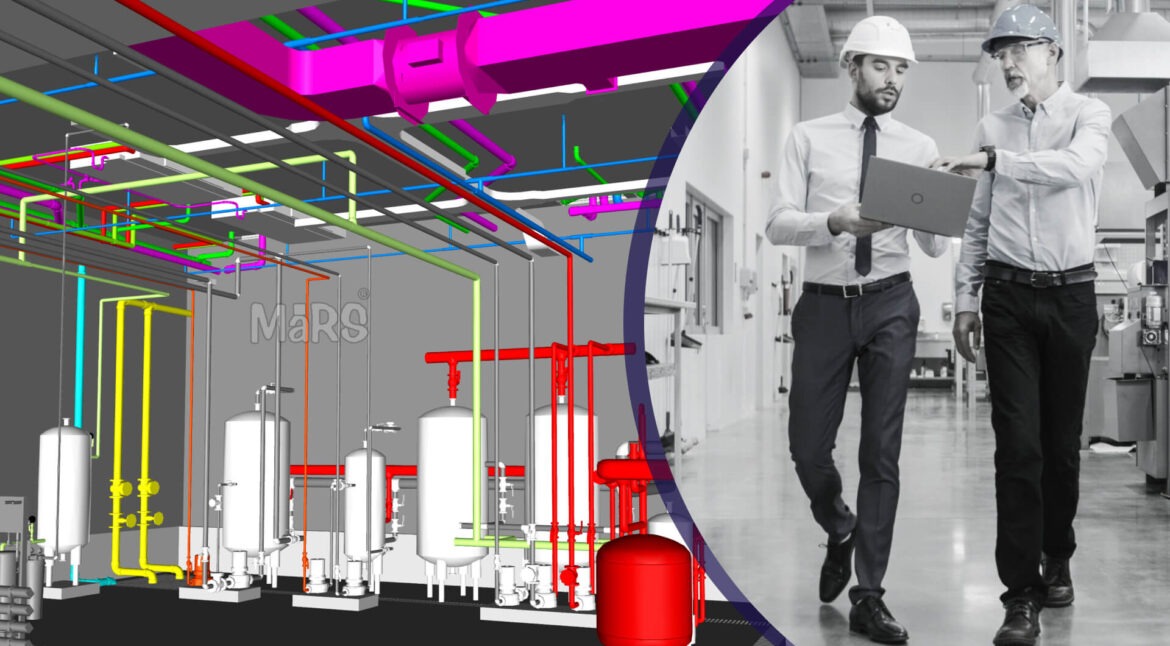

Scan-to-BIM technology integrates asset scanning technologies with BIM for more effective new construction and remodeling projects. It assists in obtaining precise As-Built conditions for increased value in facility maintenance and offers effective solutions for a new project. As-built 2D deliverables with flaws and incorrect asset data can be addressed when documenting the as-built state of complicated projects. It also makes managing costs, maintaining assets, managing time, and maintaining compliance easier.

Facilities managers can extract 2D As-Built drawings to manage continuing operations and use a centralized database for project closeouts. Thus, facility management can now have a single source of truth using this method of overcoming fragmented As-Built documentation. In this article, a detailed discussion about the Scan-to-BIM workflow and its benefits for Facilities Managers will be done.

Scan to BIM for Asset Management

When a project is handed over to clients, BIM implementation gives them access to comprehensive Asset Information Models (AIM). To run and manage building assets for global facility management, stakeholders are thinking about expanding the capabilities of Scan-to-BIM. Included in this are 2D As-Built drawings, 3D models, and additional data that needs to be merged. Facility managers can optimize facility operations and maintenance by using BIM models to regularize details.

Scan-to-BIM is a crucial tool for facility management and maintenance, but data exchange is a significant challenge. Building information for facility management duties is filtered by the Construction Operation Building Information Exchange (COBie) data structure, whereas the Industry Foundation Classes (IFC) is an open, unbiased international standard data model for BIM software. With an emphasis on operations and maintenance and facility management of assets, the COBie file includes specifications, drawings, and Bills of Quantities along with other pertinent data throughout the building’s lifetime. A particular model view specification or the IFC schema can be used to accomplish automatic and straightforward BIM and FM compatibility.

What is the process of Scan-to-BIM for Facility Management?

Implementing BIM-FM is a complicated process that needs a lot of data. Non-geometric data is usually more important to FM teams than geometric data. While identifying semantic data for integration is necessary, the construction of FM-enabled BIM models concentrates on geometric data requirements. Below is an explanation of the Scan-to-BIM workflow for facilities managers:

- Creating a BIM model with a high LOD

BIM is essential for the efficient operation and maintenance of existing buildings during the O&M phase. For efficient operation and maintenance, dependable LOD is also essential. The exact, comprehensive, and three-dimensional representation provided by LOD 500 and COBie assists with proactive maintenance planning, asset tracking, and the smooth integration of new technologies—all crucial for ensuring optimal performance throughout a building’s lifecycle.

- Data Identification based on the Element Source of Maintenance (ESM)

To ensure effective maintenance information flow between sheets and the BIM model, the element source of maintenance in a building is an essential part of the distinct degradation mechanisms. To optimize the maintenance process, Autodesk Revit software groups these components into families with shared instances, types, and parameters using a hierarchical structure.

- Creating a Link for Accessing the Maintenance Data

An API can be used to create links that access data from each ESM’s maintenance sheet inside the BIM model. Effective data processing is made possible by the architecture of the Revit software, which stores maintenance activities in Excel spreadsheets and an external database. Every ESM has a unique connection and maintenance worksheet that ensures interoperability, and each can be accessed through a link. This link enables real-time access to maintenance data within the model.

The above procedure describes how maintenance data can be integrated into the BIM model, making it easier to extract and complete maintenance sheets according to the nature of maintenance by creating a link.

Advantages of Using Scan-to-BIM for Facility Management

Using Scan-to-BIM for facility management gives structure information, allowing for the creation of a database with precise asset dimensions and information. The following are the advantages of employing this:

- Reduced expenses: With the use of 3D visualization and accurate facility inventory documentation, Scan-to-BIM helps facility managers improve asset performance and lower project risks while also bringing cost certainty.

- Data precision and consistency: Integrating various data sources improves project accuracy and consistency, improves facility managers’ presentation of data and guarantees a versatile output that adheres to regulations.

- Enhanced Collaboration: By facilitating real-time issue resolution and improved results, Scan to BIM improves stakeholder participation in projects. Facilities managers benefit from its trustworthy asset database, which helps with decision-making and scheduled maintenance.

Final Words

Facility managers can obtain a comprehensive perspective of existing facilities and systems while doing maintenance or enhancements by combining laser scanning and BIM. With the use of these Scan-to-BIM models, managers can effortlessly obtain precise, readable, and navigable asset information that is helpful for facility maintenance and future project planning.